-

San Francisco

2170 Cesar Chavez Street, San Francisco: (415) 495-4201

Free Parking at our San Francisco Location

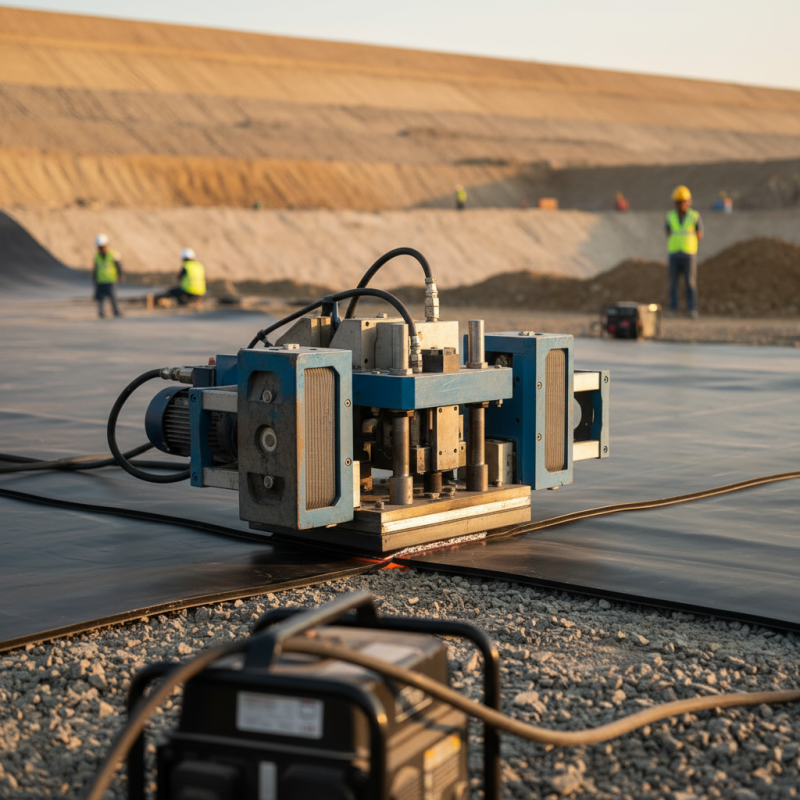

How to Choose the Best Geomembrane Welding Machine?

Choosing the right geomembrane welding machine is crucial for successful project execution. The global geomembrane market is projected to reach $3.5 billion by 2026, highlighting the growing demand for reliable welding solutions. Companies are investing in high-quality machinery to enhance efficiency and reduce costs.

Features like automatic control and temperature regulation are essential. A well-chosen geomembrane welding machine ensures superior seam quality. However, many overlook maintenance needs. Regular checks enhance machine lifespan, yet few prioritize this. Selecting equipment involves balancing cost, durability, and technology.

Research indicates that improper welding can lead to failures. Approximately 30% of projects face delays due to equipment issues. Investing in the right machine is vital for avoiding such setbacks. The challenge lies in understanding specific project requirements and selecting accordingly. Decisions must reflect a blend of experience and industry insights.

Understanding Different Types of Geomembrane Welding Machines

When selecting a geomembrane welding machine, understanding the various types is essential. There are primarily three types: hot air welders, extrusion welders, and radio frequency welders. Hot air welders are popular due to their flexibility and efficiency. They can handle a range of materials and thicknesses, making them versatile in different applications. However, they sometimes struggle with thicker geomembranes, which can lead to inconsistent weld quality.

Extrusion welders offer another approach. These machines use a heated extruder to melt the geomembrane edges together. They are particularly effective for thick and rigid materials. According to a recent industry report, extrusion welding is preferred in 70% of large-scale projects due to its strength and reliability. Yet, they can be cumbersome and require skilled operators to prevent defects.

Radio frequency welders provide an innovative solution for specific applications. They create strong seams using electromagnetic energy. While not as widely used as the others, they can offer unique benefits for thinner materials. Noise levels can be high, which may affect worker communication. Without proper training, operators might overlook critical adjustments needed for optimal weld quality. Choosing the right machine means weighing these specifics against your project’s needs.

How to Choose the Best Geomembrane Welding Machine? - Understanding Different Types of Geomembrane Welding Machines

| Machine Type | Welding Method | Max Welding Speed (m/min) | Suitable Materials | Power Supply (V) |

|---|---|---|---|---|

| Automatic Hot Air Welder | Hot Air Welding | 5-20 | HDPE, LDPE | 220 |

| Extrusion Welder | Extrusion Welding | 3-10 | HDPE, PVC | 380 |

| Peel Welding Machine | Peel Welding | 1-5 | EPDM, TPO | 230 |

| Ultrasonic Welder | Ultrasonic Welding | 1-3 | PP, PET | 120 |

| Vulcanizing Welder | Vulcanization | 2-8 | Neoprene, EPDM | 400 |

Key Features to Consider When Selecting a Welding Machine

When selecting a geomembrane welding machine, several key features stand out. The machine’s energy source is crucial. A machine powered by a high-frequency inverter can provide steady output. Reports suggest that inverter-based machines reduce welding errors by 35%. This precision is vital in projects involving environmental protection.

Another important aspect is the welding speed. Machines capable of higher speeds can significantly cut down project time. Some models offer speeds exceeding 16 meters per minute. However, faster does not always equate to better quality. A balance must be struck between speed and the integrity of the weld. Failing to do so may lead to unforeseen leakage issues, especially in landfill projects.

Ease of use cannot be overlooked. Complex controls can slow down work and increase mistakes. A user-friendly interface allows for quicker training and increased productivity. Yet, many machines fail to provide comprehensive training resources. This gap can hinder the overall effectiveness of a team. Therefore, investing in a machine that combines advanced features and simplicity is essential. Engaging with user reviews and industry feedback is advisable for informed decisions.

Evaluating Performance and Efficiency in Welding Machines

Choosing the right geomembrane welding machine can be challenging. Evaluating performance is crucial for effective welding. You want a machine that heats evenly and provides consistent pressure. This ensures a strong seal and durability. Pay attention to the temperature range and control features. It can make a significant difference during operation.

Efficiency is another key factor. Welding speed affects project timelines and cost. A machine that operates too slowly can hinder productivity. Yet, a fast machine may sacrifice quality. Finding the right balance is essential. Look for models that allow adjustments for different materials and thicknesses. Flexibility in operation can enhance overall efficiency.

Not all machines perform the same. Some may struggle with specific tasks. It's important to test performance in real conditions. Consider user feedback and experiences. Observing these factors can provide insights into long-term reliability. Reflect on your own project's needs and weigh the options carefully. Aim for a machine that meets your unique requirements.

Assessing Safety Standards and Compliance for Welding Equipment

When choosing a geomembrane welding machine, safety standards are paramount. Not all machines meet the necessary safety regulations. Ensure that the equipment complies with relevant industry standards. Look for certifications that guarantee reliability and safety. Equipment without proper certifications presents a risk. Protect your team by choosing wisely.

Tips: Always check the manufacturer's safety documentation. Confirm that the machine comes with safety features like automatic shut-off. Regularly inspect the equipment before use to identify any potential hazards.

Training is essential for safe operation. Even with compliant equipment, improper use can lead to accidents. Provide thorough training sessions for all operators. Encourage them to ask questions. Cultivate a culture of safety awareness. Workers should be able to easily point out potential risks. Remember, even a well-designed machine doesn't replace vigilant operators.

Budget Considerations: Finding the Right Welding Machine for Your Needs

When considering a geomembrane welding machine, budget is often a key factor. Prices can range from a few hundred to several thousand dollars. It's essential to assess what features you need most. Do you require portability or advanced technology? A study by the Geosynthetics Institute indicates that investing in the right machine can reduce operational costs by up to 30%.

Tips: Identify your project scope before making any purchases. This can help narrow down options and prevent unnecessary spending.

In addition, consider long-term costs. A cheaper machine might require frequent repairs. Over time, these expenses can outstrip the initial savings. The market shows that high-quality machines have a lower failure rate, saving money in the long run.

Tips: Look for warranties or support services. They can mitigate risks associated with buying a budget machine.

Evaluating your budget closely can lead to better choices. Find a balance between cost and quality to ensure your projects are successful.