-

San Francisco

2170 Cesar Chavez Street, San Francisco: (415) 495-4201

Free Parking at our San Francisco Location

Top Mechanical Parts Suppliers You Need to Know?

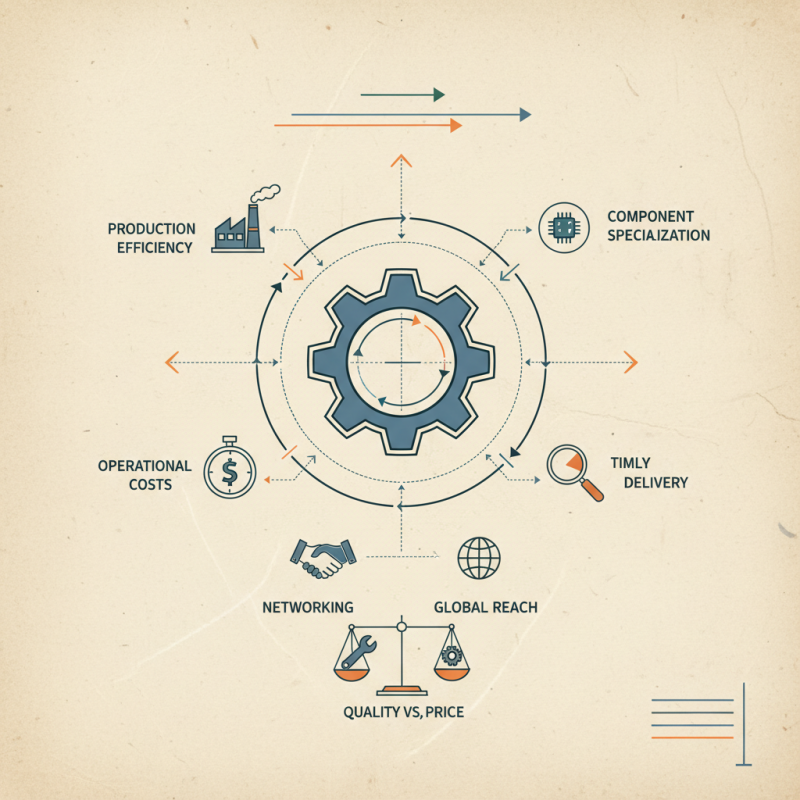

In today's fast-paced industrial landscape, finding reliable mechanical parts suppliers is crucial. These suppliers provide the essential components that drive machinery and equipment. Their quality directly impacts production efficiency and operational costs. With numerous options available, selecting the right partners can be overwhelming.

Not all mechanical parts suppliers are created equal. Some may offer low prices but compromise on quality. Others might have excellent products but lack timely delivery. Understanding the strengths and weaknesses of various suppliers is essential. This knowledge can significantly affect business performance.

As industries evolve, so do the needs for specific parts. Buyers should focus on suppliers that specialize in their required components. Research and networking will help you identify reliable partners. The right mechanical parts suppliers can ensure your operations run smoothly and efficiently.

Overview of the Mechanical Parts Supply Industry

The mechanical parts supply industry plays a crucial role in modern manufacturing. Companies rely on various parts for assembly and production. These parts include gears, bearings, and fasteners. The quality of these components can significantly impact overall efficiency.

Tip: When selecting a supplier, check their quality certifications. Ensure they meet industry standards.

Many suppliers adopt just-in-time inventory management. This method helps reduce excess stock and improve cash flow. However, reliance on this strategy may lead to shortages during high demand. Companies must maintain a delicate balance.

Tip: Build strong relationships with multiple suppliers. This increases flexibility in meeting production needs.

The industry faces challenges such as fluctuating demand and material costs. Factors like global events can disrupt supply chains. Businesses must be adaptable and proactive to navigate these issues effectively. They should regularly review supplier performance and capabilities.

Key Factors in Choosing a Mechanical Parts Supplier

Choosing the right mechanical parts supplier is crucial for seamless operations. Several key factors influence this decision. A reliable supplier should offer consistent quality. According to a recent industry report, 87% of manufacturers prioritize quality standards when selecting suppliers. Ensuring materials meet specifications can prevent costly downtime.

Another critical consideration is lead times. Delays can severely impact production schedules. Industry data suggests that 60% of supply chain disruptions stem from late deliveries. Therefore, assessing a supplier's ability to meet deadlines is vital. However, not all companies track these metrics effectively, leading to misunderstandings.

Price is also significant, but it shouldn't be the only factor. A low upfront cost may result in hidden expenses later. Some suppliers may provide subpar materials, leading to failures. Evaluating total costs over the lifecycle of the parts can provide a clearer picture. It's essential to balance cost with quality and reliability. Investing care in this selection can yield better results in the long run.

Top Global Mechanical Parts Suppliers: A Comparative Analysis

The global mechanical parts market is evolving rapidly. Recent reports indicate the market will reach $800 billion by 2025, growing at a CAGR of 5%. This growth is driven by advancements in automation and robotics. Various suppliers are emerging as key players in this landscape, yet challenges persist. Not all suppliers maintain the same quality standards.

Expert insights reveal that cost management is crucial. Suppliers often face pressure to reduce prices while maintaining quality. This situation can lead to subpar materials entering the market. Companies need to conduct thorough assessments of their suppliers. Relying on detailed reports can mitigate risks significantly.

Tips: Prioritize suppliers with strong track records. Quality should always overshadow cost. Regular audits can help identify potential issues early. Staying informed about market trends is essential. Look for suppliers adapting to technological changes. Their ability to innovate will impact product performance.

Emerging Trends in Mechanical Parts Supply Chain Management

The mechanical parts supply chain is evolving rapidly. Emerging technologies are influencing how suppliers operate. Automation is becoming more prominent. For instance, suppliers are using robotics to enhance efficiency. This trend helps reduce human error and speeds up production times. However, not every player is adapting quickly. Some struggle with new technologies, which can lead to delays.

Tips: Always assess your current technology against industry standards. Evaluate whether it meets your needs. Sometimes, the latest technology does not necessarily align with your company’s objectives.

Sustainability is a key focus in the supply chain. Suppliers are looking for eco-friendly materials. This shift reflects consumer demand for greener products. Yet, integrating sustainable practices can be challenging. Transitioning to new materials requires time and investment. Some companies may hesitate, fearing it could disrupt their workflow. The risk of being left behind is real.

Tips: Consider pilot programs for new materials. Test them in small batches before full implementation. This could help in making informed decisions while minimizing risks.

Essential Considerations for Collaborating with Suppliers

When collaborating with mechanical parts suppliers, clarity is vital. Clearly outline your requirements. Provide detailed specifications to avoid misunderstandings. Incomplete or vague requests can lead to errors. This may increase costs and delay projects. Consider the supplier's ability to meet your specifications consistently. This factor is crucial for long-term success.

Build strong relationships with suppliers. Regular communication fosters trust and collaboration. Schedule meetings to discuss requirements and performance. Feedback is essential. Be open to constructive criticism. Reflect on previous experiences with suppliers. Some partnerships may not align with your values or objectives. It’s important to identify these gaps early.

Evaluate the supplier’s capacity and flexibility. Can they scale production when needed? Assess their quality control processes. Inconsistencies in quality can harm your reputation. An effective supplier will also have a clear return policy. Understand the terms upfront. Each of these considerations ensures a smoother, more productive partnership.